Metal fabrication is the process that occurs when sheet metal or other types of metal are heated and bent to a specific shape. The pieces of metal may also require being assembled or cut. The most common types of metal used in fabrication is structural or sheet metal. Those are most often the types that require special shaping. Almost any type of building constructed today will contain several different types of metal. Here is what to expect with Fabrication in Pascagoula Mississippi.

The first step to fabrication of sheet metal is to make the appropriate cuts. This type of metal is cut with either a laser or a metal shear. The next step is to punch shapes into the metal. A turret punch is the tool used to perform that step. Metal is usually left flat while these steps are in process. After the cuts and punches are made the next step is taking the metal to press break machine. That machine is how the metal is shaped. This is the process known as “forming.”

Some Fabrication in Pascagoula Mississippi will continue with sending the metal to the welder. Not all jobs will be done after forming is complete. Welding is the process by which two pieces of metal are joined together. This bond is intended to be permanent. Welding is a skillful trade in which someone requires specific training to complete most tasks including fabricated metal. More often than not, the metal shapes turn out to be forms of art. This is especially true for structural fabrication in various industries.

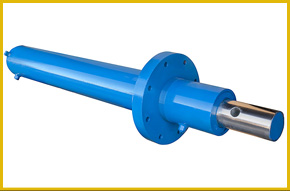

Barstock or other types of metal tubing may also purchased by fabricators. Some tubing is square and some may be round or rectangular shaped. The wall thickness of this metal will vary. It is usually referred to by the gauge. This type of metal is often used for railing. For example, the preferred gauge seems to be 10 or 11. Metal tubing provides more stability and strength than some other types of metal. This is why this type of metal is preferred for use in structural fabrication jobs. Find more information at website. You can also visit them on Facebook for more information.